LiveWall Components

The LiveWall system is engineered with high quality components and architectural grade materials, designed to stand the test of time. Our exclusive planters and rails are molded / extruded / finished in the USA, and are backed by a 15 year warranty.

STRUCTURE ASSEMBLY

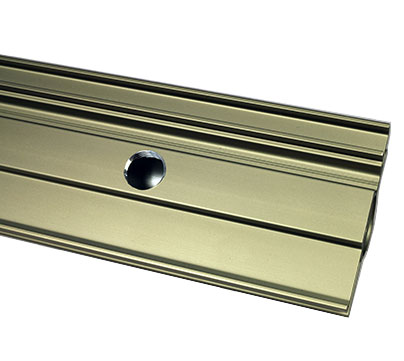

LiveWall rails are extruded from 6063-T6 aluminum, and fabricated using the highest quality standards.

- Avg. 8% post-consumer, 34% post-industrial recycled content.

- No VOC (volatile organic compound) content.

- Extraction distance is appx. 390 miles from manufacturer.

- Location of manufacturing 89 miles from point of distribution (Spring Lake, Michigan, USA).

Furring Strips (VertiRail®)

- Allows for air flow behind planter assembly

- Provides level surface for wall structure

- Z-shaped part fastened to building wall using contractor supplied anchors, typically fastened vertically along part every 12-16″

- Typically spaced 16″ on center horizontally for outdoor installations

- Typically spaced 32″ on center horizontally for indoor installations

Furring Strip (1.5″ VertiRail® for Side Irrigation Feed)

- Dimensions: 2″ wide x 1.5″ deep

- Cut to Height of living wall: stocked in 96″ lengths and 51.5″ lengths

Double Furring Strip (1.5″ VertiRail® for Side Irrigation Feed)

- Dimensions: 4″ wide x 1.5″ deep

- Cut to Height of living wall: stocked in 96″ lengths and 51.5″ lengths

- Used where two lengths of RainRail or Slot Rail ends on side-irrigation feed walls with rear-drainage assemblies (not used for walls that have bottom-draining planters)

Furring Strip (5″ VertiRail® for Rear Irrigation Feed)

- Dimensions: 4″ wide x 5″ deep

- Cut to Height of living wall: stocked in 96″ lengths and 51.5″ lengths

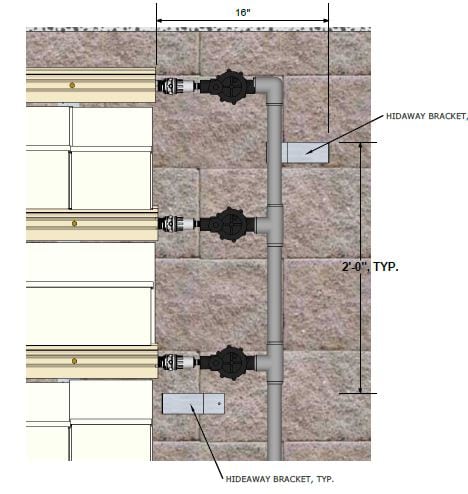

Side Irrigation Feed

Advantages

Drawbacks

Recommendations

Consider making a hinged facing material over irrigation feed lines for ease of future access for inspection and maintenance.

Facing material not yet installed

Rear Irrigation Feed

Advantages

Drawbacks

Recommendations

May require side treatment depending on site conditions and desired aesthetic. On new construction, consider recessed walls to reduce the living wall profile. For the plants to be flush with the adjacent wall surface, recess green wall area by 11 inches with Standard-sized planters and 13 inches for Large-sized planters. To conceal the thicker furring strips only, recess green wall area 5 inches.

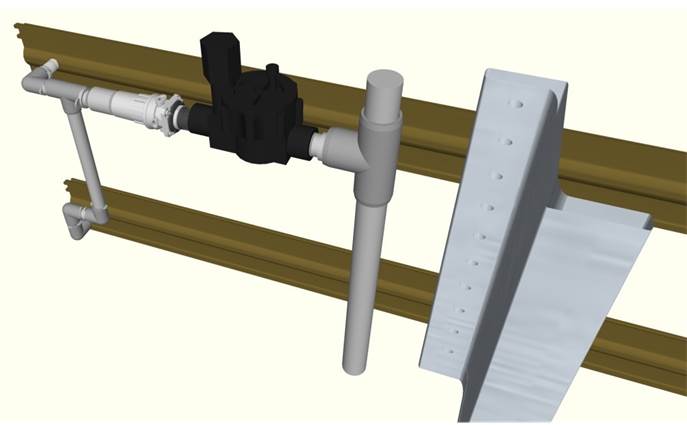

Mounting Slot Rails/Irrigation Conduit

- Anodized with champagne finish (may be custom-ordered with clear anodize, lead times and minimums typically apply)

- Slot brackets on top and bottom of rails allow for planters to simply drop in place

- Rails are spaced 16″ on center vertically with large planters, and 12″ on center vertically with standard planters

Slot Rail (H-Rail)

- Holds planters on bottom row of automatically irrigated living wall systems

- Used to hold all rows of planters on hand-watered green walls (only recommended for small scale indoor applications)

- 3.375” H x 0.5″ D with minimum 0.1” thick (sidewall)

- Stocked in lengths of 32″, 48″ and 96″

RainRail®

- Hollow rails used as irrigation conduit

- Nozzle holes spaced 16″ on center horizontally

- 3.375” H x 1.5″ D with minimum 0.1” thick (sidewall)

- RainRails are stocked in lengths of 16″, 32″, 48″ and 96″ and can be connected to accommodate any width.

RainRail® (Rear Irrigation Feed ½” Female Thread)

- Threaded holes drilled in back of RainRail for hook-up to irrigation feed behind the living wall

- For use with 5″ deep furring strips (VertiRail® for Rear Irrigation Feed)

GapTool® Spacers

- Minimum of 2 per wall structure provided for accurate horizontal RainRail® spacing.

- Available in two sizes for spacing rails to accommodate either Large planters or Standard planters.

Fasteners

- Stainless Steel Screws (302 SS 1/4 – 14 x 15″ Button Torx #3).

- Do not exceed 5 foot pounds of torque during installation.

- Selected for performance and as theft deterrent (non-standard fastener head).

- Required bit included.

WALL STRUCTURE IRRIGATION COMPONENTS

RainRail Irrigation Hook-Up

LiveWall, LLC supplies components from RainRail end to irrigation valve.

Please note: The pipe and fittings required to hookup the mainline to the valves can vary greatly by site and thus are to be sourced by the installation contractor.

RainRail Fittings

- Connects RainRail to other RainRails or irrigation feed, or caps the end of an irrigation run.

- Designed with multiple o-rings for security against leaks.

- Non-PTFE pipe lube included with each order for ease of insertion.

- Held in place against pressure displacement with included set screws, placed in pre-drilled holes.

Valves & Pressure Regulators

- Typically regulated to 25 PSI.

- The optimized valve layout is designed by LiveWall with each confirmed order’s shop drawings.

Pipe and Fittings

- LiveWall supplies pipe and fittings to connect the RainRail ends to the valves according to the shop drawing layout.

- Black LightBlock® Fittings typically used outdoors

- SCH 80 Gray pipe and SCH 40 Gray PVC fittings typically used indoors

Plant Watering Components

Nearly without exception, drip irrigation is the preferred method for watering indoor living wall systems. On outdoor systems, the preferred method can vary based upon plant type, site conditions, or local code. In most cases, outdoor green walls are watered with spray nozzles that simulate rainfall.

Each RainRail has pre-drilled threaded holes for drip emitter assemblies or spray nozzles. No tools are required nor should they be used to tighten nozzles in each rail. Over-tightening can damage parts and impair function.

Spray Nozzles

- Available in 0.1, 0.15, and 0.2 GPM flow rates.

- Molded components resistant to calcium buildup.

- If a single valve supplies water to more than one row, higher flow rates are used on upper rows and lower flow rates are used on lower rows to equalize water pressure and delivery.

- With each order, LiveWall to supply shop drawing with site specific nozzle flow layout.

Drip Emitter Assembly

- Each assembly consists of T-fitting, two 8″ long tubes, and two flow stakes

- 0.5 GPH flow stake elbows (1 GPH total per assembly) used on all lower rows

- 1 GPH flow stake (2 GPH total per assembly) used on top row, which dries out the most quickly

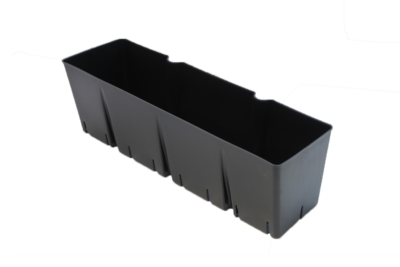

WALL PLANTERS

LiveWall planters are architectural quality moldings formed from the same polymer as car bumpers (PC/ABS).

- 100% recycled post-industrial content.

- 150 mil. thick walls.

- No VOC content

- Extraction distance is appx. 100 miles from manufacturer.

- Location of manufacturing 14 miles from point of distribution (Spring Lake, Michigan, USA).

Caution: WallTer planter modules are not designed to be climbed upon. If they are used in an area where this is a possible problem, be sure to place precautionary signage in the area of the installation to warn off would-be climbers or vandals.

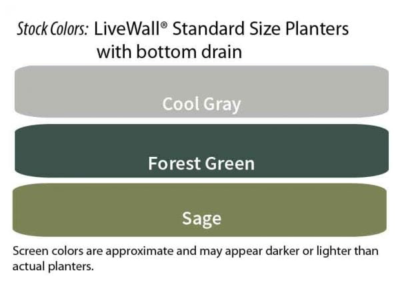

Standard Size Planters with Bottom Drain

- Typically used outdoors to grow perennials, annuals, edibles (vegetables, greens, herbs), or succulents.

- Drains out of the bottom of the planters

- Planters are spaced 16″ on center horizontally, and 12″ on center vertically

- System Weight: 15 lbs/SF (weight includes infrastructure, soil and plants)

WallTer Standard Size Full Width Planter

- Dimensions: 16″ W x 6″ D x 10″ H (12″ o.c.), soil height 6″

- Soil Volume: 0.217 cubic feet

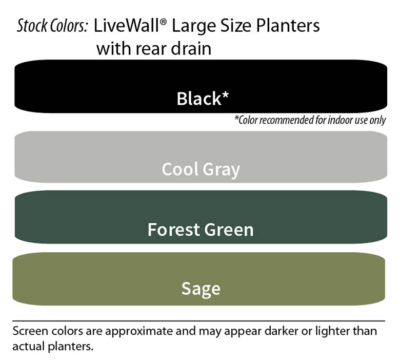

Large Size Planters

- Dimensions: 16″ W x 7″ D x 14″ H, soil height 7″

- Soil Volume: 0.4 cubic feet (twice the volume of Standard Size planters)

- System Weight: 18-22 lbs/SF (weight includes infrastructure, soil and plants)

- Planters are spaced 16″ on center horizontally and 16″ on center vertically

Rear Drain Assembly

- Used on indoor projects, may be used outdoors where water runoff needs to be contained to a single outlet.

- Spout on back of large, rear-drain planter connects barbed elbow.

- Barbed Elbows connect to 0.75″ outside diameter (0.5″ inside diameter) flexible hose assembly connected to other planters with barbed T & Y fittings.

- Assembly terminates with 0.75” male adapter (walls up to 100 sq ft) or 1″ male adapter (walls 100 sq ft or larger) for connection to installer-supplied hose for runoff containment / disposal.

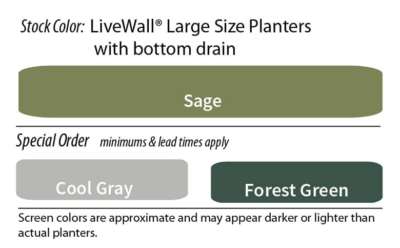

Bottom Drain

- Used outdoors to support larger perennials and grasses in cold winter climates, or to add additional moisture and root protection in hot, arid climates (e.g. in Arizona) or to grow tropical plants in subtropic and tropical climates (e.g. in Florida)

- Only stocked in Sage color, all other colors require minimum of 192 planters (approximately 340 sq ft green wall) and 4 week lead time.

MAIN LINE IRRIGATION COMPONENTS

- LiveWall typically supplies the following compatible main line components with each LiveWall order.

- Descaling and automatic fertilization components are optional, typically requested for site-specific conditions.

- Contractor to source UV-resistant fittings and pipe to connect main line irrigation components to water source and wall valves. SCH 80 gray PVC pipe and SCH 40 gray fittings recommended.

Backflow Preventer

- Backflow prevention is typically required by local code.

- LiveWall supplies a compatible backflow preventer for use with the LiveWall system.

- Contractor may alternatively source backflow preventer.

Screen Filter

Screen filters screen particles in the water to prevent the irrigation valves and nozzles from becoming plugged.

Disc Filter

Disc Filters screen particles in the water to prevent the irrigation valves and nozzles from becoming plugged. Typically disc filters used instead of screen filters for large green wall projects.

Controller

- LiveWall supplies and recommends simple controller with easy to read display and simple to adjust dial

- Available with 4, 6, 9 and 12 stations.

- Requires electricity

- Electrical wiring to be sourced by installer

Fertilizer Injector

- Recommended for living walls with drip irrigation

- LiveWall may also supply compatible fertilizer

- LiveWall may supply a liquid fertilizer concentrate.

- Follow dilution instructions prior to use (using too high of fertilizer concentration may damage plants).

Hose Timer

- In lieu of controller, valve and pressure regulators, a hose time may be used on small outdoor green walls (up to 64 sq ft) near a hose spigot.

- Fittings included to hook LiveWall irrigation feed lines and hose timer.

- Customer or contractor to supply hose.

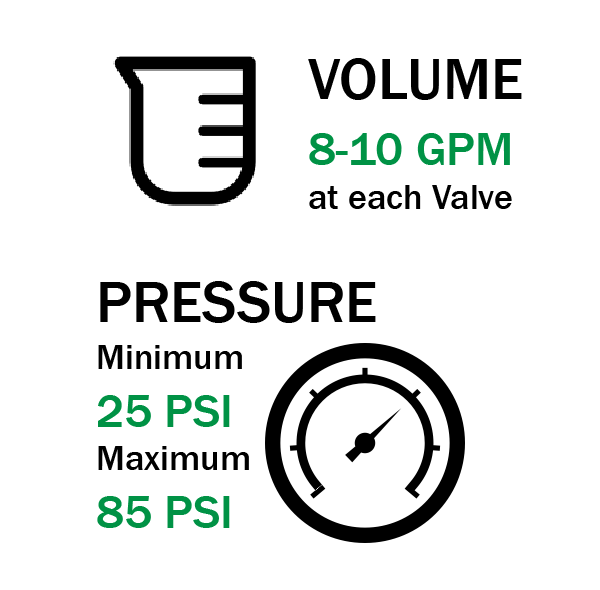

The LiveWall System requires an irrigation feed that is capable of providing sufficient water volume and pressure for each irrigation zone. The backflow preventer should be hooked up to a feed line that is at least 25PSI, not to exceed 85 PSI. Pressures over 85 PSI may damage fittings and lead to leaks.

Each valve requires 8-10 gpm per valve (zone), regulated to 15psi pressure, via pressure regulators that are placed upstream of each valve. In some cases, a booster pump may be required to ensure that the upper valves receive sufficient pressure and flow to water the planter array evenly.

LiveWall quotes mainline irrigation components for each project, and this includes backflow prevention, irrigation controller, and a micron filter to keep any waterborne debris from plugging up the irrigation nozzles. Installation contractors must source pipe and fittings to connect mainline to the irrigation valves.

Descaling Cartridges Ensure Water Flow

Properly treated hard water poses no health risks and actually provides beneficial nutrients to LiveWall plants. However, buildup of calcium or iron scaling from untreated hard water can potentially impair the flow of water through the irrigation nozzles. The cost of treating hard water is not an expensive add-on to a LiveWall System installation.

In cases of hard water, use phosphate descaling system to prevent irrigation system blockage or failure. This can be purchased from LiveWall. Descaling cartridges should be replaced annually and can be reordered from LiveWall.

Large Projects

Very large projects (over 2000 square feet) may require additional treatment. On larger walls, an alternative chemical treatment system may be preferred. In these cases, LiveWall recommends CH2O, Inc.

For a free water test to determine the type of hardness, how much is in the water, and the cost of treating 10,000 gallons of your water, send them a sample.

CH2O

4141 Boston Harbor Rd. NE

Olympia WA, 98506

Attn. Bruce Kooi

Phone: 360-259-6493

Automatic Fertilization

LiveWall systems may be purchased with a fertilizer injector that is tied into the irrigation system.

The fertigation system injects a low dose of fertilizer each time your living wall is irrigated.

LiveWall supplies an organic liquid fertilizer concentrate that must be diluted prior to use. For more information, download the injector operation and dilution instructions.

Manual Slow Release Granular Fertilizer

Outdoor walls and hand-watered indoor walls may be fertilized once annually using a granular slow release fertilizer such as Scotts Osmocote®.

A single spring application is usually sufficient to feed plants through the growing season. Shake one teaspoon of fertilizer evenly across the soil surface of each full-width, Standard sized wall planter. Apply half as much for half-width Standard size planter and twice as much for Large planters.

Manual Liquid Fertilizer

Every 6 to 12 months, indoor or outdoor living walls which do not have automatic fertigation may be fed with a higher concentration of liquid feed.

Fertilizer may be applied manually according to the label directions using a watering can or a hose.

IMPORTANT: Do not use granular fertilizer for indoor walls with automatic irrigation. The granules require water to run over the surface to activate, and LiveWall indoor systems include drip stakes that inject water directly into the soil.

Application rates will vary with formulation. In all cases, follow directions on package label.

All applications of fertilizer are the sole responsibility of the applicator.

COMPONENTS SOURCED BY INSTALLER

The components described above are typically supplied by LiveWall as a part of a wall structure’s delivered price. The following products would be sourced by the installation contractor, using components suited to each project’s specific application. LiveWall strongly recommends for designers or builder to specify desired materials to be sourced by installation contractor.

Anchors for Structure to Building Wall

Appropriate wall anchor, specify non-corrosive screw, length, head, point, and type of fastener appropriate for wall application and local codes, used to attach vertical furring strips and brackets to hold facing material covering irrigation feed. Some suggested fasteners are listed in our FAQ section.

Please Note: LiveWall, LLC provides furring strips that provide flexibility in living wall design over a number of different applications.

The exterior wall design and means of fastening the vertical garden to the building wall are ultimately the responsibility of the local architect and/or structural engineer and installation contractor.

The LiveWall system includes furring tracks, which provide flexibility in design over a number of different applications. The building wall design and means of fastening LiveWall to the wall system are the responsibility of the local architect and/or structural engineer and installation contractor and must comply with local codes. The installation contractor will be responsible to select appropriate anchors.

We contacted Fastenal and HILTI for their recommendations for various types of wall structures, and compiled them below (based on 18 pounds per square foot). Contact your preferred anchor manufacturer to confirm suitability for your application. Please note that adhesives should not be used.

| Wall Material | Fastener Type | Size | Pilot Hole | MFG/ Vendor | Part |

| Brick | Torx Hex Washer Head Screw Anchor | 1/4″ x 1-3/4″ | 1/4″ | HILTI | KWIK-CON II+1/4″ x 1-3/4″ THWH St Steel |

| ITW Red Head Tapcon Screw Anchor | 1/4″ x 1-3/4″ | 1/4″ | Fastenal | 0131211 1/4″ x 1-3/4″ Hex Washer, Hex Drive, St Steel | |

| CMU | Torx Hex Washer Head Screw Anchor | 1/4″ x 1-3/4″ | 1/4″ | HILTI | KWIK-CON II+1/4″ x 1-3/4″ THWH St Steel |

| ITW Red Head Tapcon Screw Anchor | 1/4″ x 1-3/4″ | 1/4″ | Fastenal | 0131211 1/4″ x 1-3/4″ Hex Washer, Hex Drive, St Steel | |

| Mortar Joints | Not Recommended | ||||

| Poured Walls | Torx Hex Washer Head Screw Anchor | 1/4″ x 1-3/4″ | 1/4″ | HILTI | KWIK-CON II+1/4″ x 1-3/4″ THWH St Steel |

| ITW Red Head Tapcon Screw Anchor | 1/4″ x 1-3/4″ | 1/4″ | Fastenal | 0131211 1/4″ x 1-3/4″ Hex Washer, Hex Drive, St Steel | |

| Steel Studs | Ballistic Point, Single Fastener | 0.157-1″ | N/A | HILTI | X-U 27 P8 TH

Metal “Tophat” & 8mm Plastic |

| Aluminum Studs | Ballistic Point, Single Fastener | 0.157-1″ | N/A | HILTI | X-U 27 P8 TH

Metal “Tophat” & 8mm Plastic |

| Wooden Studs | Torx Hex Washer Head Screw Anchor | 1/4″ x 1-1/4″ | 1/4″ | HILTI | KWIK-CON II+1/4″ x 1-1/4″ THWH St Steel |

| ITW Red Head Tapcon Screw Anchor | 1/4″ x 1-1/4″ | 1/4″ | Fastenal | 0131211 1/4″ x 1-1/4″ Hex Washer, Hex Drive, St Steel | |

| EIFS | Varies, fasten through Exterior insulation and finish system (EIFS) to structure below. | ||||

Acceptable Protective Underlying Materials

LiveWall systems are designed to work in harmony with a building’s ability to breathe. Furring strips (VertiRail®) are to be fastened directly to an approved framing system in accord with the siding manufacturer’s and/or general contractor’s recommendations.

Outdoor

A contractor-sourced breathable barrier system, such as Tyvek® Commercial Wrap D, works well with our vertical garden on many outdoor applications.

Indoor

LiveWall systems should use a contractor-sourced waterproof membrane such as 20 mil polypropylene or EPDM as suitable waterproof backing materials.

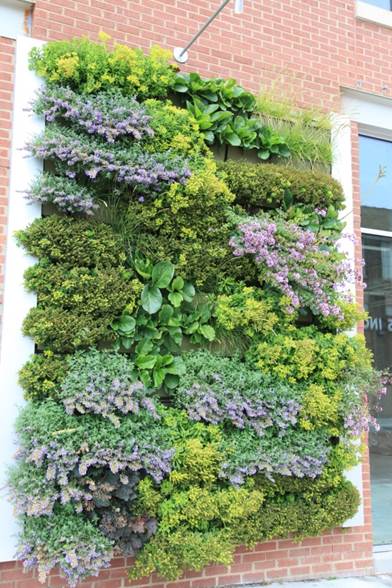

Irrigation Feed Connection and Concealment

HideAway Chase Facing Material

- Decorative treatments which can be custom fabricated to fit the architectural style of the building.

- Powder coated aluminum, wood, or other suitable material may be used for this purpose.

- May not be required for LiveWall structures with rear irrigation feed.

LiveWall system with aluminum facing material over side-feed irrigation.

LiveWall system with wood facing material over side-feed irrigation.

LiveWall system with finished facing material over side-feed irrigation—framed on all sides of each wall section.

Newly planted LiveWall system with wood facing material over side-feed irrigation—thin frame around all four sides of living wall.